![]()

December 5, 2011

![]()

I need to get the thickness sander built so I can sand the pieces of wood for my guitar neck. So, today I got my truck licensed. Now this isn't too long a story so here we go. I moved here almost three years ago. I moved to Orlando from Salt Lake City. My truck is built for extreme fourwheeling but it is also built to go down the highway. The only problem is, it burns tons of gasoline so it basically has been parked the whole time it has been here. Florida's moisture is playing havoc with it too. It has some rust spots on it and it never had any rust when I first came to Florida. That old truck and I have been to some incredible places. Take a look for yourself on my Fourwheeling Page. I needed to get it licensed so I could go get the lumber for the thickness sander so I did just that. After sitting in the DMV for over two hours, I was done and off to Lowes I went. Oh, but let me back up. I have been needing a drill press and Harbor Freight put their 12 speed drill press on sale. I have breakfast with some men from my church on Monday mornings and Harbor Freight is in the same shopping center as the restaurant. I went straight from breakfast to buy the drill press, after okaying it with my wife, and they were out! They had a truck that had just come in so they checked but there were none on it. They thought they would have one in on Thursday. Sure enough they got one in so they held it for me today until I could get up there and buy it. At Lowes, I bought 5 2x4's and one sheet of cabinet grade 3/4" plywood. This will be plenty to build the thickness sander. I got some help loading the plywood but couldn't get it out of my truck with my back like it is so I cut off 36 inches which is enough for the table and the motor mount for the sander. Then I was able to get the wood into the garage. My poor skill saw has been destroying any wood it comes near so I decided that I had better buy a new blade. I don't want to splinter all the 2x4's and I sure don't want to mess up that beautiful plywood, expecially at $45 a sheet. So I bought a blade for the 2x4's and fine kerf blade for the plywood. I think instead of using my bench saw to cut the plywood, I will clamp a guide and use my skill saw. I just want to make sure I don't waste any wood.

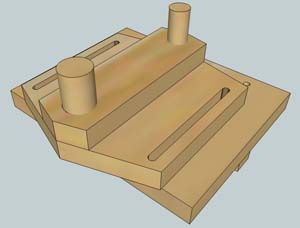

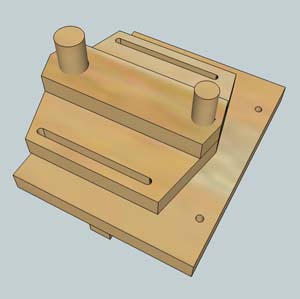

I sat down out in the garage and assembled the drill press but there were no instructions with it. I got almost all of it together but have one screw and one piece of metal that I can't figure out where they go. I went on Harbor Freight's website and found an online manual but I still can't figure out where those two parts go and I'm not sure how the chuck stays in the drill. I'll take a look again a little later. Now, the last thing I did today was design a circle cutting jig for the thickness sander drum. I'm going to need around 25 3/4"x5" circles and I need something that will help me make them as similar as possible. They say that you need to take a piece of 3/4" ply with course sandpaper and "true up" the drum once you get it built but if I can start with the circles being very close in size, it will save me a LOT of time. I had an idea that I came up with so I sat down with AutoCad while I let my back rest from doing all the other stuff today and came up with an idea. After I got the circle cutting jig drawn in AutoCad, I set out to draw it in Google Sketchup. Sketchup is somewhat similar to SolidWorks but MUCH easier to use but it won't do as much as SolidWorks either and I am just learning so I'm limited on what I can do and how fast I can do it. After I drew the jig, I realized that the screws and wing nuts that hold the assembly together might interfere with the wood as it is being turned in the jig so I had to add another piece to the top to raise

it above the wingnuts. You can see what I'm talking about in the images. After spending a few hours on the jig, I went out to the garage, right about midnite and cut the three main parts and glued the top together and drilled the 1" hole.The drawings show a 3/4" hole on the opposite side but I think I will leave that out of my jig. Click Here to see my page about the circle cutting jig. |